top of page

Boeing-Morphwing Senior Design

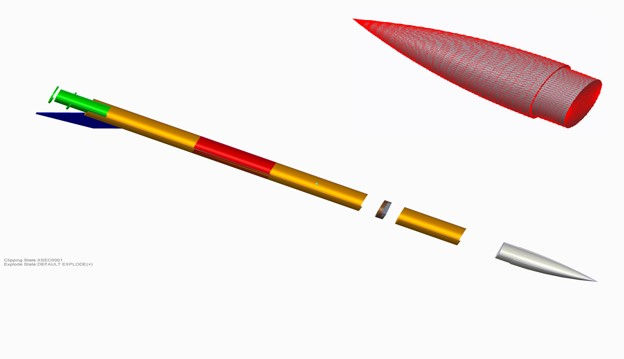

• Sponsored by Boeing to create a model flexible wing in line with the theoretical idea of a continuous trailing edge flap.

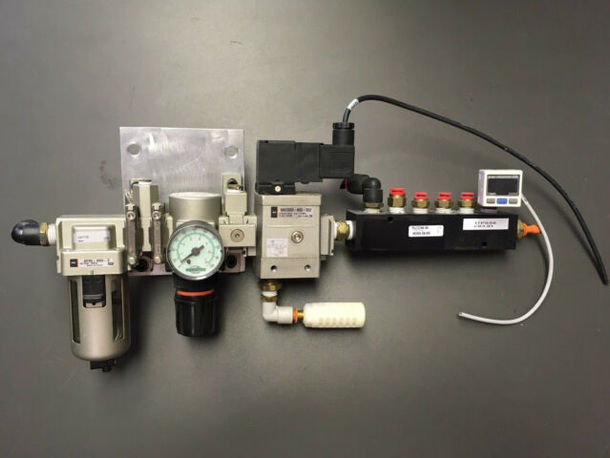

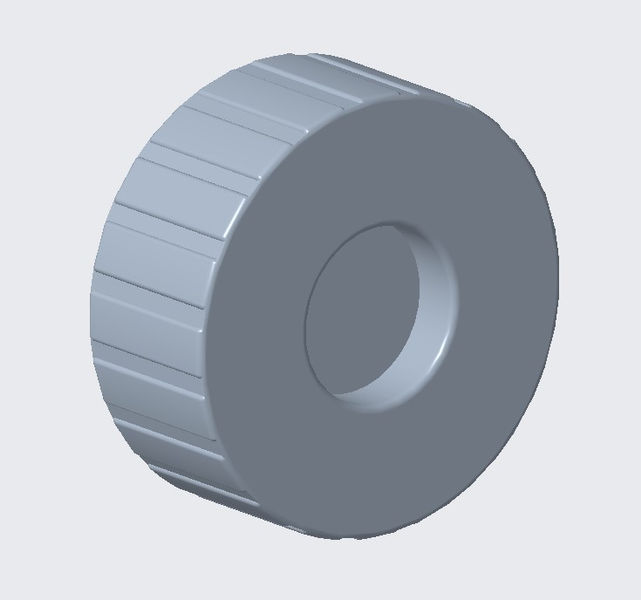

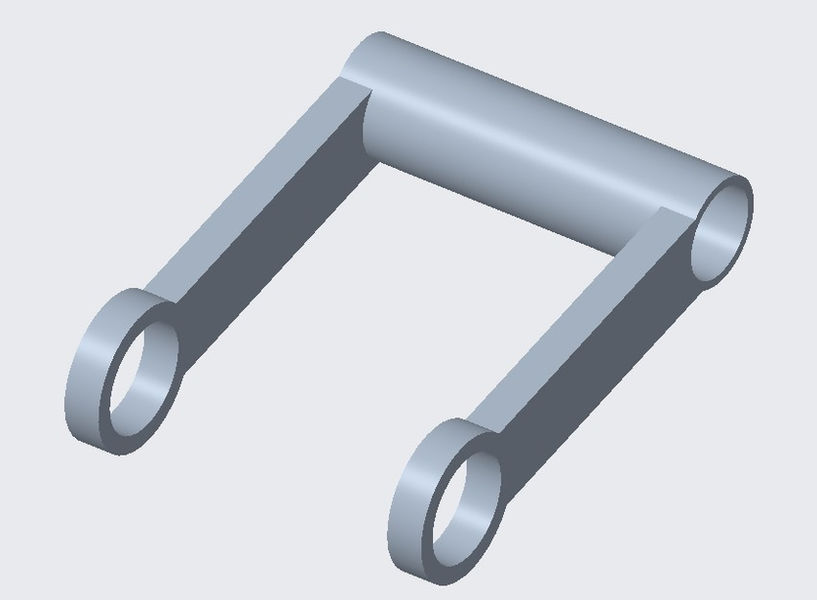

• Formulated the mechanism for a continuous flap actuation system using a series of timing belts & pulleys, gears, and servo motors.

• Constructed structural components of the wing using materials like aluminum, carbon fiber, and nitrile sheets.

• Performed all Rapid Prototyping, Machining, and fabrication activities to manufacture the tabletop model from aluminum sheets & rods.

• Lead the Design, Controls, and Manufacture team of 7.

• Restructured airplane flap systems for drag optimization and boosted fuel efficiency as well as flight range.

• Assumed accountability in testing stimulations for application in Boeing 747 aircraft on ANSYS.

• Designed a 3D scale model of the concept in PTC Creo and it’s drawings for the machining as well as CNC of its parts.

• Administered budgeting for manufacturing of the scale model in alignment with available market products.

• Devised manufacturing guidelines for the manufacture of the tabletop model.

bottom of page